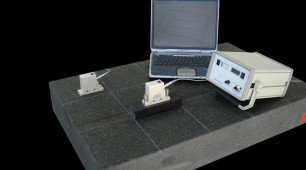

Granite measuring machines have a wide range of uses in various sectors:

production control, engine bases and shafts, laboratories, metrology departments, die- sinkers and machine tool production. To make sure that each instrument is within the tolerance required, inspection is indispensable.

On-site inspection at the customer’s facility:

As far as plane surfaces are concerned, Zali generally intervenes personally at the customer’s facility with the appropriate tools for carrying out the inspection. The precision of the surface is restored but breakages are not necessarily resolved.

On-site inspection at Zali’s own facility:

This is the optimum solution because, besides correcting precision, both breakages and pitting are eliminated by means of grinding the upper layer.

The instrument may then be considered as good as new. Furthermore, the degree of precision may be considered to be better than it was originally.

Periodic inspection:

This is an arrangement to be agreed upon with the customer, based on the frequency of use of the instrument; costs may be reduced if there are various cases to be attended to at the same time.